Problem

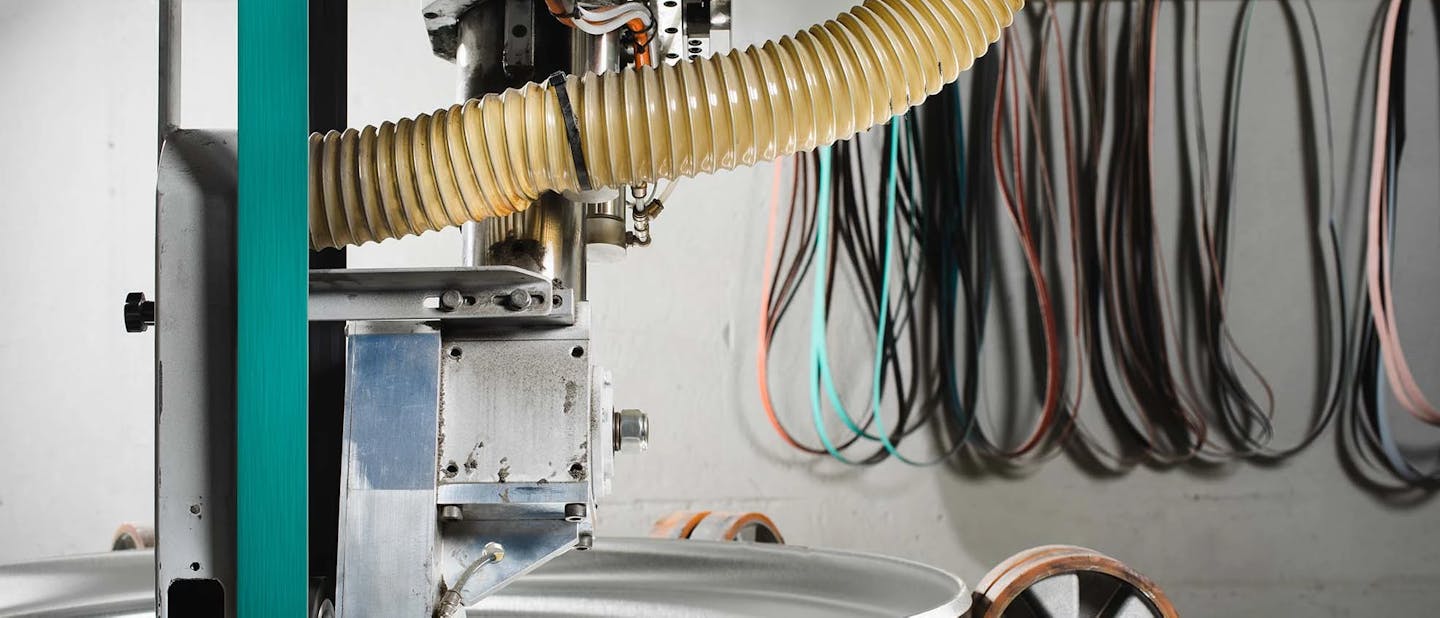

In the world of industrial production, we often face challenges that require both technical sophistication and inventiveness. One such example is company X, which faced a specific challenge in its production process. Due to frequent staff changes and changes in the operator's workstation, there was a need for readjustment and improvement in the use of the Costa contact grinder machine.

The key challenge was a 1.5 mm thick stainless steel plate with cut-out holes, which was slightly curved due to internal stresses in the material. Until now, the plate had only been processed with basic grinding techniques, but there was an urgent need for higher quality processing and process efficiency.

Our approach

The Eurol team tackled the precise adjustment of the grinder. In the first phase, they decided to debbur the plate, and in the second phase, to grind it using a non wowen belt. Due to the specific shape of the workpiece, a 'very fine' grit non wowen was chosen, allowing for less aggressive grinding, not sharpening the already debbured corners, and ensuring an aesthetic surface.

"The non wowen abrasive belt is significantly less aggressive than traditional cloth abrasive belts. Therefore, they are a more appropriate choice in such situations. Additionally, it is more robust and resistant to the sharp edges of the workpiece if it has not been previously annealed," said the CEO of Eurol.

Result

This approach saved the client many hours of manual labor and significantly shortened the process, which had previously been done by hand. The contact grinder ensured repeatability, meaning that every workpiece looked the same under the same grinder settings, which manual processing does not guarantee.

Advantages for the client

Optimized contact grinder machine

20% savings on abrasive material consumption

Up to 70% time savings in labor due to the automation of grinding